WINDER / ROVING / ROTOR / RING

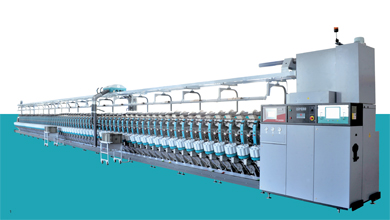

ISPERO-M Automatic Winder

Optimized Yarn Path Design

Excellent Building of Yarn Package

Itelligent Joint Cycle

Great Fexbility of Splicers

Total Control of Yarn

Quality

Double Tension Section Electromagnet Pressurized

Reduction of Power Consumption

First Class After- sale Service

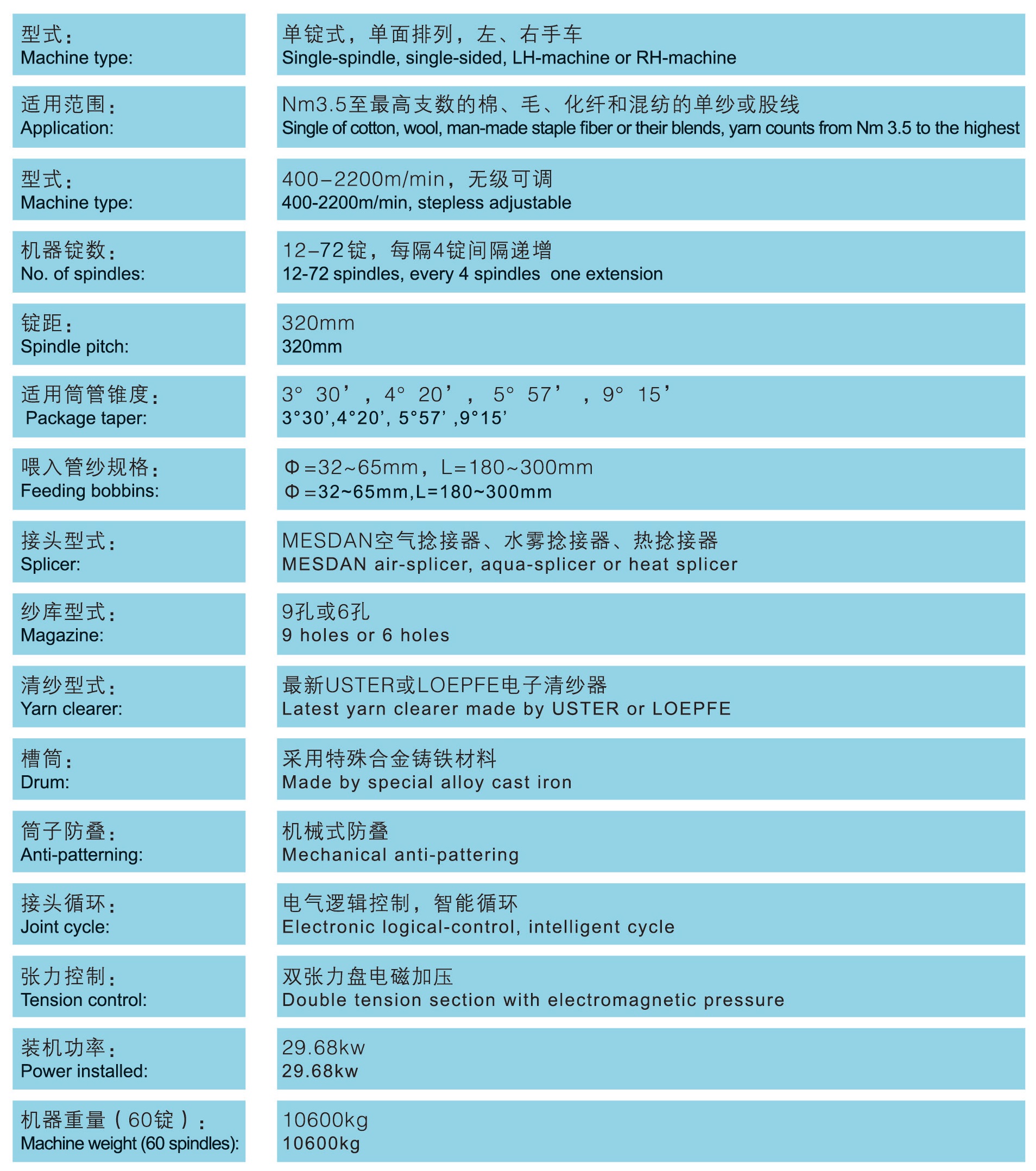

ISPERO-M Automatic Winder

Production with perfect Quality and Excellent Modern technology

12-72 spindles 2200m/min Intelligence

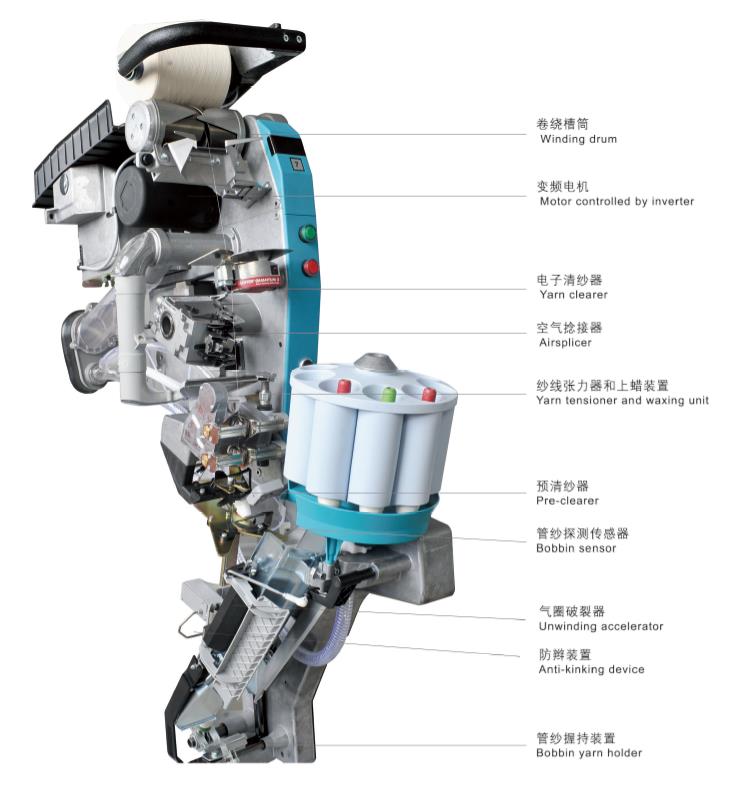

ISPERO-M automatic winder is a new generationwinder self-developed by CHTC Qingdao / Sino Machine Group. It inherits perfect winding technology andextensive material adaptability, adopts optimizedyarn path and advanced electronic control technology intellectual controlled splicing cycle. Electrical controlinstead of mechanical drive simplifies machinestructure and realizes complete yarn monitoring. This winding technology ensures higher productivity, betteryarn quality and outstanding economic efficiency.

Higher productivity

Optimized yarn path, excellent unwindingaccelerator, efficient joint cycle.

Superior yarn package and yarn quality

Best Design Mechanical anti patterning. plus electronic anti patterning., USTER QUANTUM3 and LOEPFE ZENIT yarn clearer, MESDANsplicer, imported drum, double tension sectionelectromagnet pressurized.

Reduction of power consumption

Main suction motor controlled by inverter,jointcycIe controlled by sensor and independent motor.

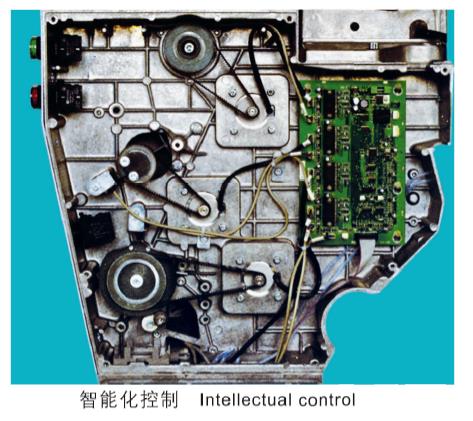

Intelligence

The control subsystem composed of micro-control unit and digital signal processing works independently and interlinks with each other; With embedded monitoring system, software can be upgraded online; mechanical structure is simple, easy to disassemble and assemble, maintenance workload is reduced.

HMI dialogue

Complete and clear display of each single spindle's LED Ialarm,Multi-lingual touch screen, convenient for data setting and production data statistics.

First class after-sale service

Excellent professional after-sale service team, fast fittingssupply.

Intellectual yarn fault treatment

Automatically adjust yarn suction length of big nozzle according to different yarn fault type.

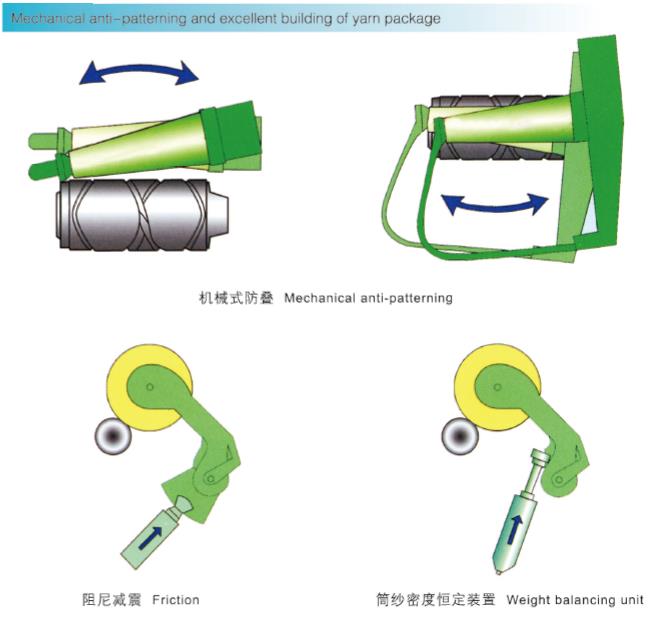

Best Design of anti patterning. and with excellent Quality of yarn package

The clearer controls real-time winding process from the movement it activated, if thread is broken or yarn fault occurs, the clearer producesthe immediate lifting of the package from winding drum and package finish braking. The absence offriction between package and drum prevents yarnworn.

Perfect anti ribboning

Patterning is effectively avoided by an oscillating movement on a vertical and horizontal plane ofpackage holder cradle. The winding drum speedis kept constant through all the winding process.Uniform and constant package density

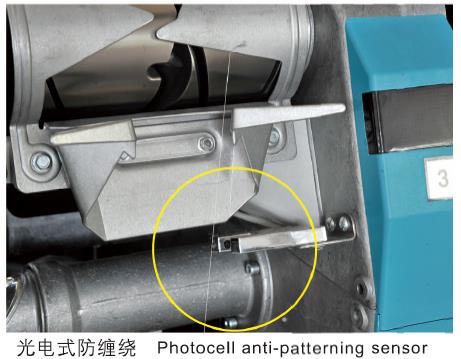

Electronic anti ribboning device

The drum speed is control-led by the machine PC, and changes its value

(electronic anti patterning system) only at the pre-set package critical diameters.

The drum speed variation and frequency are set on the machine PC.

The system operates also during the acceleration after the splicing cycle.

Patterns on the package are minimized for a better use in the downstream processes.

Axial displacement (optional) can also be used for dyeing package in combination with the electronic anti patterning

Package cradle is pneumatically pressurizedto eliminate drum vibration. The uniformityof package density on all winding head isguaranteed by centralized setting.

Intelligent oint cycle and winding monitoring

Flexible cycle

Thanks to the individual motors and PC, the splicing cycle is automatically made, as per the actual requests of the splicing steps, improving, as consequence, the efficiency and production of the winder. Consequently:

Greater productivity

Consistent package quality

(no presence of double yarns or yarn scrambling)

Power and compressed air

savings because unnecessary splicing cycle are avoided

Minimum wear of the parts

Minimum yarn waste

1 Independent movement of the package yarn suction nozzle

2 Independent movement of the splicer

3 Independent movement of the bobbin yarn suction nozze

4 Independent movement of the yarn tensioner device

The inspector control system controls each action of joint cycle and headstock sets parameter so that it can obviously shorten splicing time, enhance production efficiency, reduce unnecessary action, compressed air consumption and lints .

When yarn winding on drum or belt yarn etc abnormal condition is found, photocell anti-patterning sensor immediate alarms and stops so as to enhance efficiency and guarantee package shape and precisepackage length.

The LED display of each spindle can show two Chinese words or one English word and show both state and spindle alarm messagefor treatment by maintenance worker.

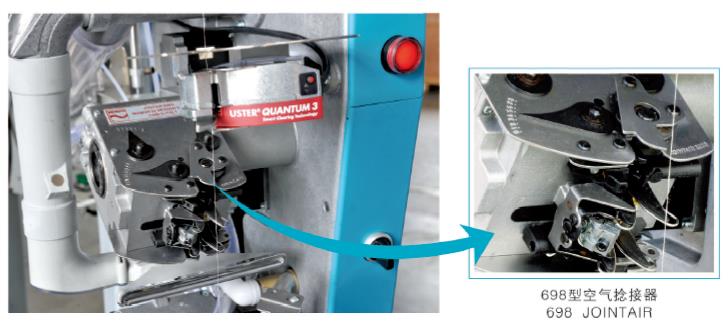

Great flexibility of splicers,guarantee of fine joint quality

Strategic Cooperating with the leading splicer manufacturers worId wide to guarantees fine joint quality to suit and higher the trend of textile industry.

698 Jointair

Different chambers and covers can be adapted to suit the splicing of cotton, wool, manmade fiber and their blends.

4923 Aqua-splicer

Aqua-splicer is mainly suitable for the splicing of slub yarn, core spun yarn and compact ring spun yarn etc various kind of fiber.

4983 Heat splicer

Heat splicer is applicable for the splicing of pure wool/ wool -polyester yarn.

Top level electronic yarn clearer, total control of yarn quality

Yarn clearer controls yarn quality during all winding process including

joint quality. Twodifferent kinds of yarn clearer settings are adopted for

normal winding and joint.

Computer Aided Tension The winding tension is detected continuously by the Tensor, which interacts with the yarn tensioner device, through the machine PC, in order to adjust the load on the yarn as required. The Tensor, being positioned just before the drum detects on line the real winding tension. The sensor does not have any movable parts and performs also as “antiwrap system”.

Tensorflex (standard)

In presence of elastomeric yarn blended with wool/cotton the tension values must be diversified during the package formation to ensure a perfect shape.

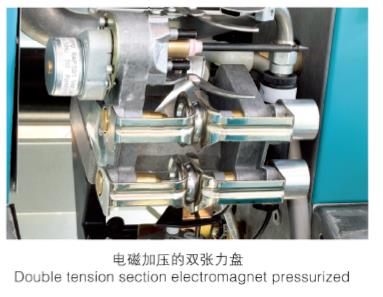

Double tension section electromagnet pressurized

Package start with yarn deposit control

Acceleration can be set via the computer. The operator sets the optimum acceleration each time according to the work parameters (count and material, waxing, etc.) thus allowing a perfect drive of the package with a regular deposit of the yarn he computerised control system automatically adapts the acceleration ramp as package diameter varies.

Uniform yarn tension and waxing

Double section yarn tensioner electromagnet pressurized with centralized pneumatic setting guarantees an uniform winding tension, since tension is divided into two points. The centralized setting on headstock for tension section according to yarn type can meet the requirement of lot change on one machine. Tension close loop control system guarantees package shaping and uniform density. Large, oscillating pressure washers for a constant, effective control.

Waxing device (optional)

Yarn waxing is obtained by a positively driven and adjustable deflection device. The double section tension device guarantees uniformity of wax application.

Air jets keep the yarn tensioner and waxing unit free from dust.

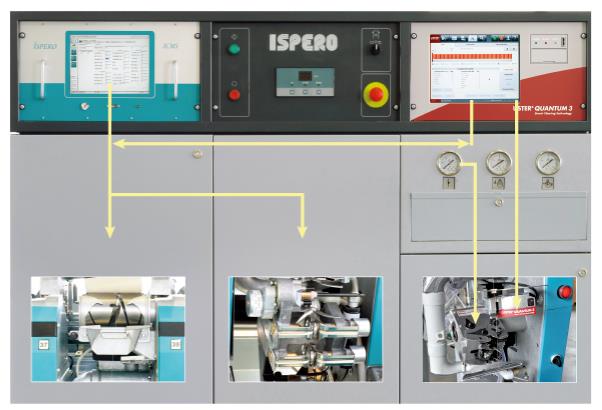

Convenient inspector and control system can save the productions information of 15 days

The inspector control system coordinates the automatisms, gather data and provide an interface with the operator.

All parameters of the winding process are controlled by the Computer:

Yarn quality

Package qulity

Productions quality

Conrol of all peripheral units

Energy consumption

Gradual acceleration of winding drum with a preset sequence for optimum yarn deposit on the package and precise yarn length.

Continuous dialogue with electronic clearer for exact reading of yarn fault dimension, consumption and classification of yarn fault.The Computer has a large touch screen and an USB port. The data are displayed in a descriptive and graphical form.

Auto-diagnosis with immediate identification of the cause of the fault for minimizing spindle down-time.

The inspector Control System centralized control yarn tension and ensure good package shape.

Spindle Monitoring System Each winding head is equipped with an alarm monitoring system.The operator is notified in real time of the ongoing alarm. Each spindle indicates technological as well as functional alarm.

The inspector Control System and pneumatic panel jointly control each twisting parameterand efficiently control joint quality.