CARDING COTTON

JWF1215 broad

width card

Carding system with biggest area

Optimized carding element-excellent carding efficiency

Modular design- for easy operation and maintenance

New type of mechanical structure and driving method

New type of entity chute

National initiated pre-draft system

Precision leveling system

Technical specification

JWF1215 broad width card

Representatives of high production and high efficiency

JWF1209 broad width card is the latest generation of high production card, developed by Sino Machine Group,CHTC QTM, based on the idea of high production, high efficiency, high quality. Benefit from extensive application of hi-tech material and adjustment of card core- carding area, production of JWF 1209 can reach 150kg/hour and sliver delivery speed reach 400m/min.As machine width increase to 1.5m,card sets fit is reduced, so the investment cost such as area occupation, labor, energy consumption can be greatly saved.

Guarantee and measures of high production and high efficiency:

☆ More than 60 years card development experience

☆ More than 120 thousands card production experience.

☆ Advanced processing equipments

☆ Width increase to 1.5m

☆ Adjust structure of carding area and increase carding area by 74%

☆ Extensively apply hi-tech elements

☆ Integrated design of card, chute feeder, pre-draft and autoleveller

1.Licker-in 1st mote knife

2.Licker-in 2nd mote knife

3.Liocker-in segment

4.Licker-in

5.Back stationery flat

6.Cylinder enclosed undercase

7. Cylinder

8.Al-alloy rotary flat

9.front stationery flat

10.Doffer enclosed undercase

11. Doffer

12.Three roller clearer

13.Three roller

14.Upper chute feeder

15.Feed roller

16.feed plate

17.Open roller

18.Statistic pressure case

19.Lower chute feeder

20.Circling fan

21.Chute output roller

22.material slot

23.Control cabinet

24.Pre-draft coiler

25.Cotton guide wheel

26.Draft roller

27.Guide roller

28.little calender

29.directive feed plate

30.Feed roller

31. Cross apron

32.Bigcalender

33.front undercard suction point

34.Cylinder undercase suction point

35.Licker-in 2nd noil suction point

36.Licker-in 1st noil suction point

37.Licker-air bleet suction point

38.Rear /lower web cleaner suction point

39. Rear /upper web cleaner suction point

40.Rear flat trash suction point

41.Flat fly suction point

42.Flat trash suction point

43.Front flat trash suction point

44. Front/upper web cleaner suction point

45.Front/lower web cleaner suction point

46.3-rollers suction point

47.Web cleaner suction point

48.Coiler suction point

Chute feeder section

Pre-draft section

Leveling section

Filter section

Carding section

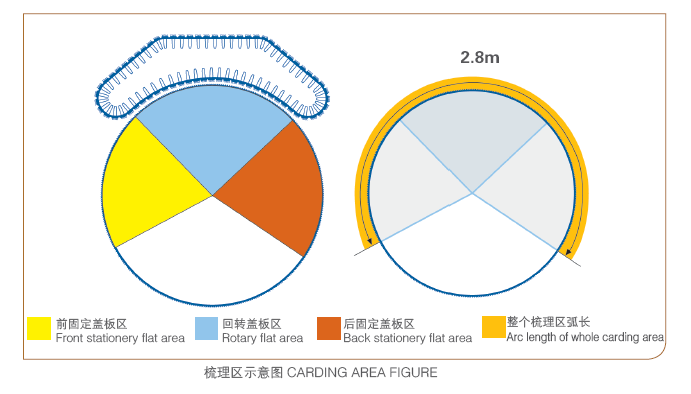

Carding system with biggest area

Guarantee of efficiently removing neps and trash

☆ Working width increase to 1.5m,carding area increase by 50%,greatly enhance production.

☆ Adjust the structure of carding system : lift up cylinder and down doffer, increase arc length of carding area to 2.76 m,increased by 74% compared with traditional carding area.

☆ Directive feed mechanism can reduce fiber damage. New type of feed plate make cotton feed more clear.

☆ Special single licker-in is mounted two mote knife, pre-carding segment around licker-in to efficiently exclude trash and short staple.

Carding area

Front stationery flat area

Rotary flat area

Back stationery flat area

Arc length of whole carding area

Optimized carding elements

Excellent carding efficiency

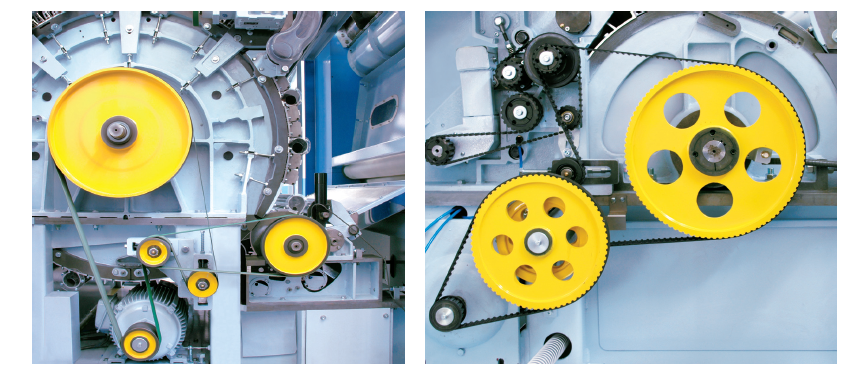

☆ Hi-Tech Al-alloy stationery flat is featured by light weight, stable running, convenient adjustment. It is driven by two tooth belts without need of other fasten part. Therefore it is featured by easy mantling and dismantling, convenient maintenance.

☆ Tandem stationery flat, web cleaner and Al-alloy sheet is made by Al-alloy profile, featured by good tip neatness and convenient gauge adjustment to ensure fiber carding more fully and fine.

Modular design:

☆ Licker-in section adopts single licker-in and three-licker-in modular design and two noil area can be easily adjusted outside machine. Mote knife under licker-in and clean unit can be used for adjusting noil quantity to reduce fiber loss.

☆ Tandem stationery flat, web cleaner, Al-alloy sheet can be configurated and fit in different group according to material, featured by flexible mantling and dismantling, good trash excluding efficiency.

New type of mechanical structure and driving method

☆ Step entity frame welded by steel plate, flexible and simple mechanical structure, special machining technology ensure gauges precision.

☆ Adoption of multi- independent motor plus vector enhances automation and precision of technological adjustment.

☆ Pneumatically controlled turnover cross apron is favorable for observing web.

1 Cylinder:big torque independent motor, motor direct start with stable running.

2 Rotary flat:Independent motor+ vector inverter,stepless speed adjustment,suitable to different material and different technology.

3 Doffer:Independent motor+ vector inverter,stepless speed adjustment,solve the problem of big sliver count fluctuation during acceleration and deceleration.

4Feed:Independent motor+ vector inverter,stepless speed adjustment,levelling system can greatly increase sliver irregularity

New type of chute feeder-JWF1175

☆ New type of chute with big capacity supply cotton stably and improve sliver evenness and weight irregularity efficiently.

☆ Air is circling inside chute to make batt more even and stable.

☆ Feed plate is pressurized by spring so fiber is hold elastically. Distance between feed plate and feed roller is automatically adjusted according to batt thickness.

National initiated pre-draft system-JWF9503

Specially designed for high production card, the pre-draft coiler with drawing technology can greatly increase sliver delivery speed and lay a foundation for heavy sliver count set .

☆ 3 up and 3 down rollers with guiding roller, double area draft can realize 3 folds draft.

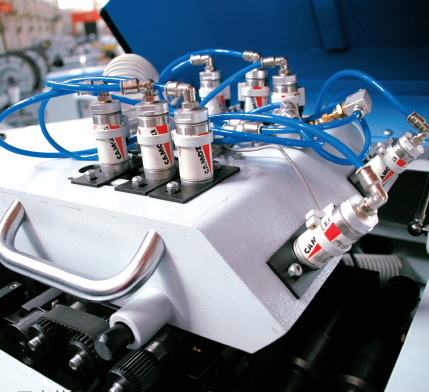

☆ Rubber roller is pneumatically pressurized to make pressure even.

☆ The whole system is driven by independent motors.

Precise leveling system-FT029

Core of sliver CV

FT029 autoleveller is specially used for directive feed mechanism, whose working principle is following: take chute pressure variation to leveling system; control batt status through PID control; detect batt thickness variation by use of precision vertex non-contact sensor to control fiber in short term and detect sliver thickness variation to control fiber in long term, both of them make up of open –close loop control; fit with vector motor to enhance drive precision and ensure sliver CV value.

Long-short term autoleveller

1 Detect chute pressure

2 Detect feed batt

3 Detect sliver delivery

4 Adjust feed roller

5 Feed roller driver

6 Short term control sensor

7 Long term control sensor

Technical specification

Application:pure cotton, chemical fiber and blends in length from 22 to 76.

Output(kg/hour):150

Sliver delivery speed (meter/min):400

Sliver count(g/m):3~12

Feed weight(gram/meter):450~1500

Working width(mm):1500

Total draft folds:37.5~500

Chute upper feed roller working diameter(mm):Φ172

Chute open roller working diameter(mm):Φ292

Chute lower feed roller working diameter(mm):Φ156

Feed roller working diameter(mm):Φ100

Licker-in working diameter(mm):Φ250

Doffer working diameter(mm):Φ706

Doffer working speed(rpm):4~90

Cylinder working diameter(mm):Φ1288

Cylinder working speed(rpm):320~460

Pieces of rotary flats(working flat/total flats):30/84

Flat speed (mm/min):98~370

Attached carding segments:Licker-in carding segment 2 pieces

Front stationery flats 8 pieces(cotton)

Front stationery flats 12pieces(chemical fiber)

Back stationery flats 10 pieces(cotton)

Back stationery flats 14 pieces(chemical fiber)

Web cleaner:front 3, back 3(cotton)

No (chemical fiber)

Suited can (mm)Diameter:Φ1000

height:1100,1200

Continuous air suction volume(m3/hour):5000

Statistic pressure at exit(pa):-1000~-1300

Compressed air pressure (kg/cm2):6~7

Air consumption(m3/hour):0.75

Total power installation:17.8KW(including card, chute and autoleveller)

Safety cover type:totally enclosed

Machine net weight(kg): about 12200

Coiler type:Φ1000×1100/1200(Model JWF9503 pre-draft coiler or model FT209A linear can-change coiler )

Profile dimension(L×W×H)(mm):5871×2480×3525