CARDING COTTON

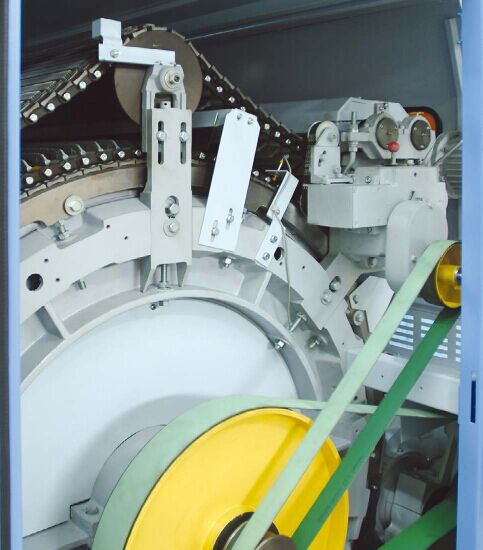

FA231C HIGH PRODUCTION CARDING MACHINE

Specially used for lap.

Microcomputer control and digital display relative parameter.

Inverter-controlled feed roller and doffer drive for stepless speeds.

Adoption of synchronous toothed belt for driving with steady running and low noise.

Visible plastic adhesive filtering pipe with smooth surface.multi suction point on card for continuous suction with good suction efficiency.Continuously pressure detection;

New type carding segment under licker-in are fitted and oluminum alloy front and rear stationary flats.

New type cross apron for sliver guiding,free of maintenance,easy operation.

Totally-enclosed safety covers are of reliability,convenience and beautiful look

There are many automatic stop motion devices.

There are front and rear web cleaners fitted.

New type of metallic card clothing with high quality.

In reverse direction of cylinder running flats increase carding action and improve web quality.

For flat stripping the comb is replaced by the brushing roller and cleaning roller.

CYLINDER & LICKER-IN

The construction of driving cylinder and licker-in with flat belt is simple and its starting is smooth and stable.

DOFFER

The doffer is driven by an inverter and a synchronous belt which permits stepless variations of the speed.

CROSS APRON

New type cross opron for sliver guiding, free of maintenance, easy operation.

FEED ROLLER

Feed roller is driven by an electronic frequency converter which permits stepless variation of its speed and is controlled to be synchronized with doffer by the computer.

MULTI SUCTION POINT

Multi suction point on card, continuous suction, pressure continuous measure.

FLATS

Reversed revolving flats increase carding action and improve wed quality. For flat stripping comb is replaced by the brushing roller and cleaning roller.

PRESSURE MECHANISM

Special pressure mechanism provides the consistence between the pressure and the measurement.

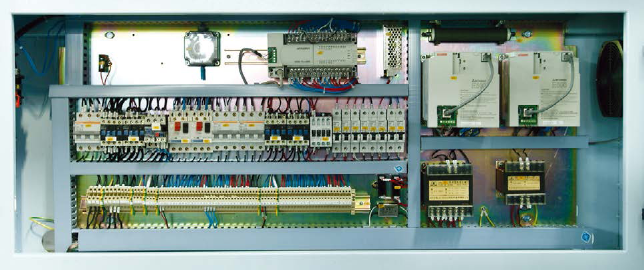

DESIGNED AS AN ENTIRETY

Electronic control cabinet and safty-cover are designed as an entirety with beautiful profile.

ELECTRIC CONTROL SYSTEM

There are imported PLC and two imported invertersin the electronic control cabinet of card FA231C. It controls doffer's and feed motor's speed to make a stepless variable speed and run it at the rate, with a smooth speed up and down, it is running steadily and reliably.

The imported display screen is erected on safty cover in the left front of machine.It can control each motor. It can display all data on dynamic technoloyy and take an alarm for all faults and full-can status,Control center of whole machine is a imported

programmable controller ,which operates simply and reliaby.

TECHNICAL SPECIFICATION

Applications: This machine is used for processing cotton,chemical fibers and blends in length 22-76mm

Production (kg/h):60

Delivery speed (m/min):180

Sliver count (g/m):3.5~6.5

Feed weight (g/m) :400~800

Working width (mm): 1000

Total draft: 98〜177

Cylinder diameter (mm): 1288

Cylinder speed (r/min): 326 356 428

Doffer diameter (mm): 706

Doffer speed (r/min): 6~60

Licker-in diameter (mm): 250

Licker-in speed (r/min): 674 736 803 886 967

No.of revolving flats(working/total): 30/82

Flat speed (mm/min): 77~309

Attached carding segments: Front stationary flat(3), Rear stationary flat(3),Carding segment under licker-in

Can size (mm): DiameterΦ600 or Φ900,Height 1100 1200

Continuous Suction (m3/h):Air volume 3500

Air pressure (Pa):-920

Motors (kw): Total installed power6.784

Motor for main drive 3.8 Motor for cleaning roller of flat strips 0.37 Motor for cleaning roller 0.55 Motor for doffer 1.5 Motor for cleaning brush for flats 0.007 Motor for feed roller 0.55

Safety cover form: Totally-enclosed structure

Space requirement (L x W)( mm): 3442×1916(Coiler no included)

Approx net weight (kg):About 5500